Assembly Systems

AMT is not only a supplier of fastening technology, but rather as a turnkey supplier for complete assembly workspaces and assembly stations. Due to our extensive experience in the construction of assembly systems, we are the ideal partner if solutions from one source are desired.

Manual Assembly Workspaces

The setup of an assembly workspace for tightening operations normally requires more than just the selection of nutrunners and controller. Often special handling devices are required to guide and support the tools. In addition to this are other components to guide and/or workers and for visualization like monitors, light columns or operator panels. The selection of the correct socket by the worker may also be defined and examined through the use of controlled socket boxes. If you also integrate sensor systems to monitor the exact spindle position, a complete control and documentation of the fastening process is possible.

Hand-Guided Multi-head Nut Runners Semi-automatic

Complex handling devices are planned by our design department in 3D-CAD and presented to our customers. After any required modifications, the handling devices are assembled in our workshop and put into operation. Every customer can completely test their assembly workstation at our facility before delivery.

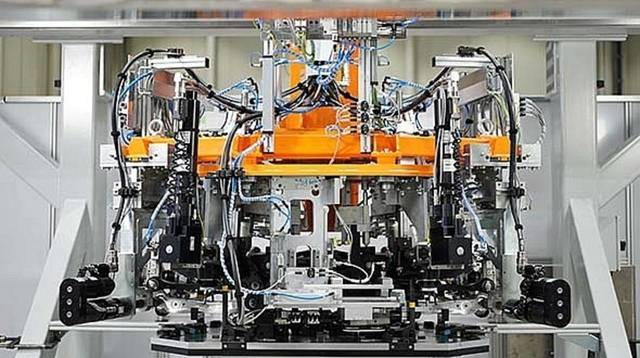

Automatic Assembly Stations

Several nut runner spindles are integrated into a tightening station. Where the tightening process is done automatically. The parts to be assembled are placed manually.