Hardening Machines Induction hardening. Individually. Precise.

The Hardening Machines division has been developing and producing induction hardening machines for a wide variety of components, which are used both by our customers around the world and in our business areas, since 1952. To date, a large number of hardening machines have been supplied and installed in numerous production lines for automotive, truck, bus and agricultural applications. Our customers appreciate our high level of competence and reliability. We offer the right hardening machines and hardening processes for a wide range of applications. We analyse customer requests and special requirements and implement them to ensure maximum satisfaction. Customised machine developments, laboratory tests and test hardening on our own laboratory machines are further components of our product portfolio.

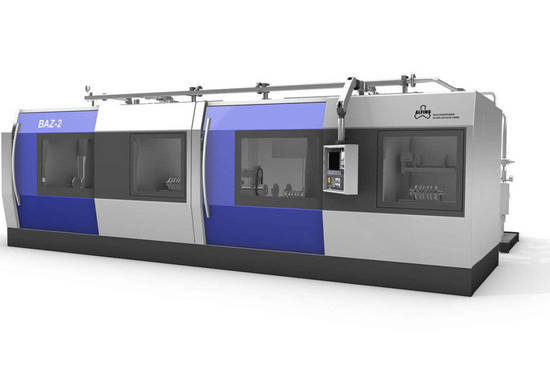

Hardening Machines

Hardening machines for automotive crankshafts

Our machine types BAZ-2 with 1 or 2 stations, as well as type FAST-NG offer the optimal solution for crankshafts up to 700 mm. They are specially designed to meet the requirements of the automotive industry and offer the ideal solution for crankshafts for passenger cars and other vehicles.

Hardening machines for truck / bus / agriculture crankshafts

Maximum flexibility for machining a wide range of crankshaft types and variants up to 1.5 m is offered by our Flex 1.5 machine type. Customized solutions and options ensure that this type can be perfectly matched to specific requirements.

Hardening machines for large crankshafts

The perfect solution for crankshafts up to 4.5 m is offered by our machine type Flex 4.0. Due to our own crankshaft production we have a comprehensive understanding for the requirements and challenges and could incorporate all our experience into this machine type.

Hardening machines for powertrain

Our machine types VHM and UHM offer the ideal solution for almost all applications in the powertrain sector. The modular machine design and the option of feed or total surface hardening allow adaption for specific requirements.

Inductors

A hardening machine is only as good as the inductors used as the central tool. For this reason we develop and manufacture our inductors in-house. Our experienced employees manufacture all inductors with first-class materials and the highest level of craftsmanship. From the manufacture of the components for the heating loops and housing through to the assembly of the finished system, everything is "Made by Alfing".